Essential Oil Production

Since essential oils have been known thousands of years, there are a lot of different methods available for collecting essential oils from the plants. While it is important to note that method of essential oil production is unique to every plant, most essential oils are obtained using one of the following methods: “Distillation”, Extraction” and “Mechanical Expression”. New methods such as CO2 extraction, Microwave assisted distillation and historical methods such as Enfleurage are also used in essential oil production. There are some basic principles to ensure the quality of essential oils before their isolation methods. First of all, quality of the essential oils begins with the quality of the plant material. The genus, species and the age of the plants, their growing altitude, soil and water quality are some of the factors which affect amount and quality of the essential oils. The main reason why we obtain Orlife essential oil from the first producer is to guarantee the quality of essential oils starting from their first production place.

Distillation

Distillation Methods:

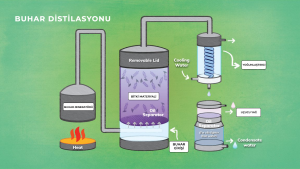

Distillation is the most common and traditional method for the isolation of essential oils. It is applied in three different ways depending on the nature of plant material: “water distillation, “water and steam distillation” and “steam distillation”. All three methods are subjected to the same principle which is based on volatility of essential oil. In general, during distillation, steam plus volatile essential oil components of plant material are condensed back into liquid form through cooling. Since essential oils float on water, separation is occurred easily.

Regardless of the distillation method, distillation still has three basic parts: a heating chamber or steam generator, a condensing tube and a collection still. Outside of the condensing tube is cowered with cold liquid, usually water to reduce temperature of the vapor quickly. Water and essential oil are collected in the collection still after passing through the condensing tube. Collection still is called “Florentine flask” and designed to allow easy separation of essential oil and water. Essential oils are mostly float on the water since most of them are lighter than water. However, certain essential oils such as cinnamon and clove are heavier than water. For that reason, collection still or “Florentine flask” should be selected according to the density of essential oils.

Traditionally, distillation system called Alembic has been used for the distillation of essential oils.

Water distillation:

Water distillation:

The plant material is completely placed in water which is boiled by applying heat. After water begins to boil, the vapor and essential oil mixture rises into condensing tube and condensed in collection still. High heat application to water and plant material is the main disadvantage of water distillation since high temperature can damage the structure of the essential oil constituents. Water distillation mostly used in local productions and is generally applied to dried and hard plant material. For example, pine turpentine essential oil is usually obtained by water distillation. In addition, traditionally rose oil which has large production areas in Turkey and Bulgaria, is obtained by water distillation from past to present.

Water and Steam Distillation:

In water and steam distillation, the plant material is macerated in water to ensure diffusion of water deep into the plant. Then, steam is passed through the plant material to take off essential oil from the plants and condensed in cooler. The steam can be generated either in a steam generator or in the still in which plant material is above the boiling water. Similar to water distillation, water and steam distillation is also widely used in rural areas for local production.

Steam Distillation:

In direct steam distillation, steam generated outside the still is passed through the plant material. In this method, plant material is not directly heated, heat is applied to the water, which produces steam. In this way, steam distillation allows for collection of delicate and temperature sensitive aromatic compounds. It is the most widely accepted process to produce essential oils on large scale. For example, large scale lavender essential oil production is performed by steam distillation.

The aromatic water obtained together with the essential oil is also valuable and is called as “hydrolat” or “hydrosol”. In general, the composition of hydrosol is very similar to essential oil. Some of the substances in the essential oil that are highly soluble in water pass into the hydrosol. The most well-known examples are rose and lavender hydrosols. Since 99.95% of hydrosol is water and very little of aromatic compounds, using hydrosols are safer than essential oils. At the same time, it has a short shelf life because of its high water concentration. Hydrosols should be stored in cool places and used as fresh as possible.

References

Başer, K.H.C., Buchbauer, G., 2015. Handbook of Essential Oils: Science, Technology, and Applications, Second ed. CRC Press, Boca Raton, FL.

Buckle, J., 2015. Clinical aromatherapy – Essential Oils in Healthcare, Third ed. Elsevier Health Sciences, London, UK.

Tisserand, R., Young, R., 2013. Essential Oil Safety: A Guide for Health Care Professionals. Elsevier Health Sciences, London, UK.